Aircraft Problems: Should I Be Worried?

A look at the various problems we see in aircraft engines

One of the main purposes of oil analysis it to find problems that might be developing in an engine, and after doing this for a lot of years, I can say without a doubt that it works. However, some problems are more urgent than others, and part of our job is to determine if a problem is a major one or not. Most engine problems start out minor but if left unchecked can lead to major issues, which eventually result in an engine’s demise.

Minor problems

Abrasive Contamination

Dirt getting past the air filter will cause a lot of problems in an engine, and piston scuffing is the primary concern. Fortunately, most air filters do a really good job even when they are dirty. If you change your air filter on a regular basis, then this type of problem is pretty easy to avoid, but remember, it’s also important to check the whole air induction system down-stream of the air filter to make sure no cracks or other problems exist that could be letting dirt in.

Fuel dilution

This generally includes any fuel level between 1.0% and 3.0% that keeps showing up again and again. This is not a normal situation, but it doesn’t necessarily cause an engine problems in the short term. Still, since fuel is a contaminant, it will cause the oil to oxidize faster that it normally would. That typically causes problems like stuck oil control rings, which leads us to our next minor issue.

Oil Consumption

This one isn’t really a problem at low levels because all engines are designed to use some oil. What you really want to watch out for is a change in how much oil is being burned. If you always use 1 quart every 10 hours and it suddenly jumps to 1 quart every 3 hours, then you know something has changed. That’s part of the reason we ask about oil added between changes. If you’re not losing oil due to a leak, it’s either getting past the rings or the valve guides. Granted, you can buy a lot of make-up oil for the cost of a top overhaul, but there will probably come a time you’ll have to bite the bullet and fix the issue.

Corrosion

If you fly around 5 hours per month, that should keep this minor problem off you mind, though we all know that life doesn’t necessarily allow this. Still, if corrosion is minor it should easily disappear once the engine is back to flying regularly. If corrosion gets so bad that it causes pitting on the parts, that’s when the problem elevates to major status.

Major problems

Cam spalling

This one is often directly related to corrosion getting out of hand, though it can also be related to oil starvation on things like cold starts and high RMP starts. It takes time for that thick oil to get circulating through the engine and if it doesn’t get to the cam and followers fast enough, metal-to-metal contact happens. Problems of this nature won’t necessarily cause an engine to fail, but can lead to loss of some power, which might be needed to clear that 50’ obstacle at the end of the runway.

Excess Heat

This is really a pretty broad category and is often due to operational factors, though it’s almost always avoidable if you are paying attention to your cylinder head temperatures. If those are getting too hot, then maybe the cooling baffles aren’t quite working like they should. Maybe you have a crack in an air induction tube. That could allow abrasive dirt into the combustion chamber, but would also cause that one cylinder to run leaner than others (due to extra air being sucked in) and likely hotter. Excess heat causes the parts to expand more than they were designed for and that’s when wear starts getting heavy.

Stuck or Burned Valves

Abrasive contamination, fuel dilution, and oil consumption will all contribute to this type of problem. Sticking valves can be identified by things like morning sickness (not necessarily in the morning), intermittent rough running, and high mag drops (not due to a fouled spark plug). Burned valves are usually pretty easy to spot with a borescope though might not necessarily cause major operational problems until they burn to a point where compression has significantly degraded.

Detonation

This issue develops in an engine when the combustion process is not completed correctly, usually when an engine is under a heavy load and producing a lot of heat. It can easily burn a hole right through the top of a piston, resulting in all of the oil in your engine being pushed out the breather tube and oil starvation (see below). If your engine had a good muffler, you would hear a ticking or pinging noise, but since those don’t exist in general aviation, this problem can often go unnoticed without the help of oil analysis and/or engine monitor data. If this problem exists, running a richer fuel/air mixture to keep the engine cooler should help.

Instant failure

Oil starvation

Whether it’s caused by oil consumption left unchecked or severely worn bearings not letting oil get to all of the parts, this type of problem will cause an engine to fail in short order and it’s usually accompanied by the worst sound your engine can make — silence.

Spun bearings

When the babbit is worn off your bearings, either due to hard use, abrasive oil, or lack of oil, you will start to lose oil pressure. If the problem gets severe enough, the spinning shaft will actually weld to the bearing itself and spin in place. Once this happens, the engine is pretty much shot, though amazingly enough it might still run (but not for long).

Outside causes

Of course there are lots of other things that can cause instant engine death — see the first cartoon on this link for an example, or, although it’s not a plane, this picture of my flooded MINI. Unfortunately, outside factors probably take more engines down than anything else.

It’s pretty rare for engines to fail suddenly due to minor issues, so when we see something going on, that doesn’t necessarily mean you need to get out the wrenches or head straight to the engine builder and demand a repair. Usually, you’ll have some time to see if the problem persists or is getting worse. Once that has been established, then some action will likely be required to keep the engine going, but the cost should be minor compared to the hassle and expense of having to replace the whole engine. So test your oil every now and then. Chances are good your engine will look perfect, but if it doesn’t, you’re better off knowing about it sooner rather than later.

Related articles

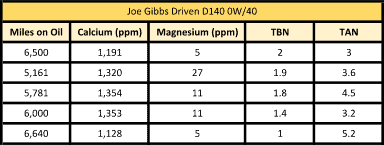

TBN/TAN: Do You Need One?

What exactly is a TBN or TAN, and do you really need one?

Sampling Methods

Does it matter how you take a sample?

The Renuzit Experiment

Is ZDDP really necessary?

The Lower Unit Blues

Water contamination in a marine lower unit