What are Insolubles?

The insolubles test measures the total insoluble materials in an oil sample — that is, all solid or liquid materials that are not soluble (won’t mix) in with the oil. We test insolubles using the centrifuge method. A measured volume of oil is mixed with a heated solvent, agitated, and spun at high speed. Insoluble materials collect at the bottom of a tapered glass test tube and can then be quantified. The insolubles level indicates how fast the oil is oxidizing and how effectively the oil filtration system is functioning.

Virgin oils shouldn’t have more than a trace of insolubles in them. The insolubles in virgin oils are from the normal oxidation process of the oil, which leaves free carbon in suspension when oxygen forms with hydrogen (oil is a hydrocarbon). Or they can be from additives that have fallen out of suspension.

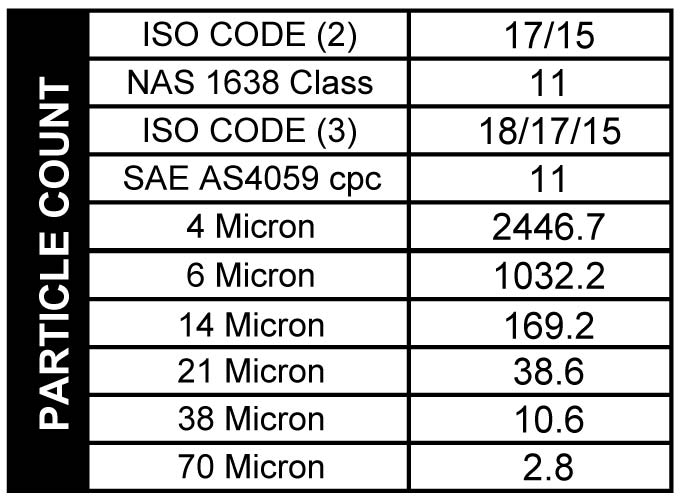

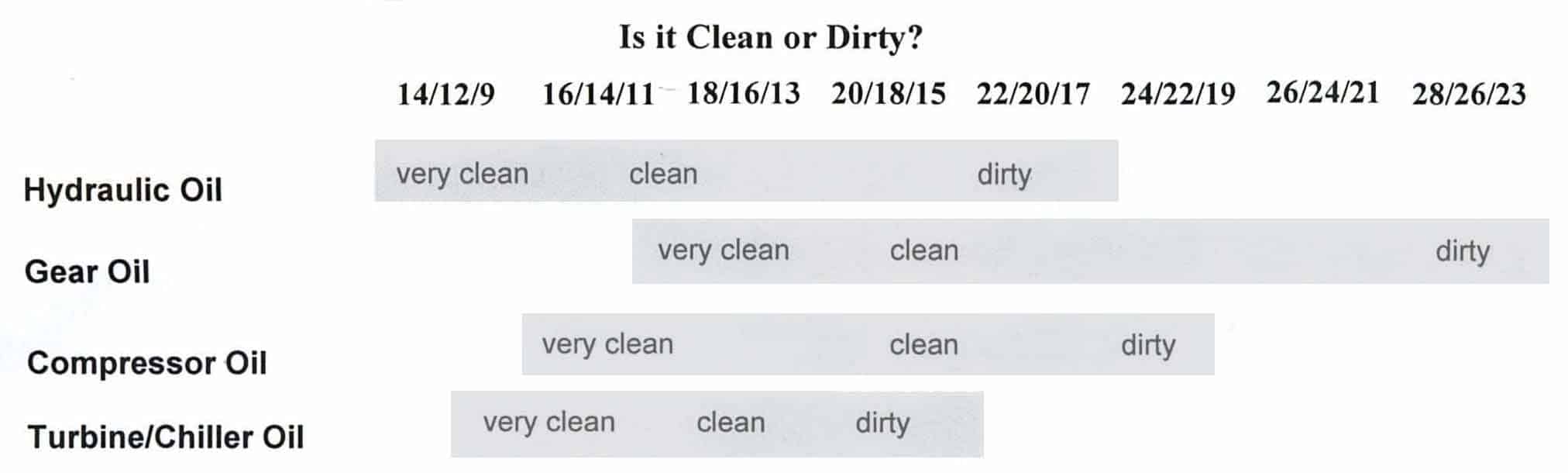

Industrial oil normally contains a very low level of insolubles due to the few and relatively mild heat cycles the oil experiences (heat cycles accelerate the oil’s normal tendency to oxidize). Further, oil filtration on industrial machines may filter particles as small as 2 to 10 microns, keeping the oil pristine for a very long time, often years.

Automotive and aircraft oils however, suffer the most difficult environmental problems of all types of oils we analyze. They regularly receive blow-by products from the combustion process, and they suffer extreme heat cycles. Any contaminant will accelerate the oxidation process, causing insoluble materials to increase. Because excessive solid material in the oil limits the oil’s ability to lubricate effectively, an engine oil with a high level of insoluble material needs to be changed.

Excessive insolubles can form if the oil or engine is running hot, is receiving more than a normal amount of contamination or blow-by, is suffering more (or more severe) heat cycles than is normal, is being run longer than a typical use cycle, or, on the other side of the coin, if oil filtration is marginal or relatively ineffective.

If we found no contamination in your oil and your oil change intervals are normal, we often mention a problem at oil filtration as a possible cause of higher insolubles. Your oil filter may be inferior, or it is possible the oil filter bypass valve has relieved if the filter is becoming restricted. The filter system bypass may also open upon unusually cold starts when the oil is too thick to pass through the filter media. Once the bypass relieves, the filter is effectively out of the system.

The insolubles test is a fair measure of several possible problems in your engine. One high reading needn’t be a cause of concern. Several high readings in a row merit investigation of what the problem may be.