Soot: How Much is too Much?

What is soot & why does it matter?

Blackstone offers percent soot testing as an optional test above and beyond what we do in the standard analysis. It’s something many of our diesel customers have shown interest in. It can be challenging for people to understand how much soot is a problem and how much is normal, so in this article we’ll shed some light on our testing process and what it can tell you about the health of your engine.

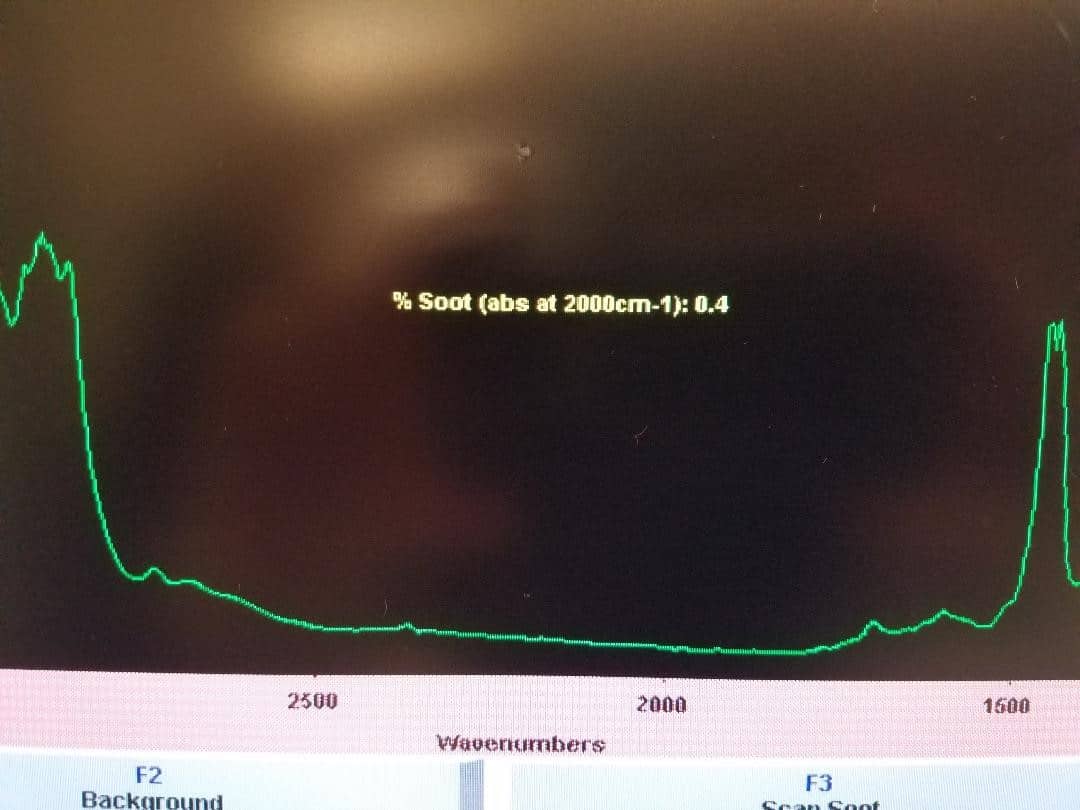

Here’s a brief run-down of how it works. We use an FTIR (Fourier Transform Infrared) spectrometer to measure the percentage of soot present in an oil sample. Essentially, soot raises the absorption rate of the infrared light spectrum and when an infrared beam is shot through the sample, the rate of absorption is measured and quantified. The lab operator ensures the machine is running properly by performing a series of check standards, including calibrating against a known 2.0% soot sample to ensure accuracy.

Okay, nap-time is over. So what is soot and what impact can it have on an engine? Soot is a natural by-product of internal combustion. Soot is the reason diesel engine oil turns black, sometimes only after a few miles. When it becomes excessive it can thicken up the viscosity, leave deposits on wearing components, and ultimately clog a filter (or perhaps worse, an oil passage). Excess soot can have an abrasive component and has the ability to stick to wearing surfaces, potentially increasing oil consumption.

A used sample from a Volkswagen 2.0L TDI. Soot reads at 0.4%.

We like to see soot at 1.0% or less; anything higher than 2.0% to be cautionary. So what does that mean to you? In layman’s terms, excess soot can indicate a combustion problem. Pinpointing that problem (or problems) can be a bit more difficult, but there are a couple fairly simple things to check if you think you’re seeing excess (or just more than normal) soot in the oil. Make sure that the fuel system is maintained and properly calibrated so that the injectors are operating at peak efficiency and with a proper air/fuel ratio. Also check for intake leaks and make sure that the air filter is clean and serviceable. Make sure injection timing is set correctly as well. Change the oil and filter regularly to prevent soot build-up.

It’s always possible that excess soot is due to a mechanical problem too, and that’s obviously a bit more involved than just changing the oil or swapping out a dirty air filter. Excessive ring clearance is a common cause of excess soot. Keep an eye on oil consumption as increases in that area can also show a developing ring problem.

Several of our customers have installed by-pass filtration systems in an effort to keep soot lower and the oil cleaner in general, and that can be effective. Employing an oil analysis regimen can also be helpful in assessing wear metals and other contamination like soot…but as a Blackstone customer, you already knew that!

Related articles

The eBay Oils (Part 2)

Part 2 in our series on oil additive packages from the old days

The eBay Oils (Part 1)

What kind additives did oil have back in the old days?

Ryan’s Cholesterol

What do cholesterol and oil analysis have in common?

Blackstone and the Post Office

Why does the post office take so long?