Rebuilding a GM 350 Engine

This is a story of my first complete rebuilding an engine. The engine is a GM 350 V-8 out of a 1984 Chevy Custom Deluxe pickup truck. The truck was custom in that I’m fairly sure no other truck is rusted in exactly the same way, and deluxe in that both windows still roll down.

I purchased this truck in 1999, and one of the sales points of the truck was the engine. It started up and ran well, though it had a super high idle that did not want to drop down after the engine warmed up. The vehicle doesn’t have an RPM gauge so I can’t say exactly how high it was, though it was so fast that I did not need to step on the accelerator after a stop light and it would get up to about 35 MPH on its own. I figured this was a carburetor problem and could be addressed later.

I was in love with the truck and had to have it. I didn’t even bother to do an oil analysis on it before I bought it, partly because I felt I could fix anything that went wrong and partly because I was scared at what I would find.

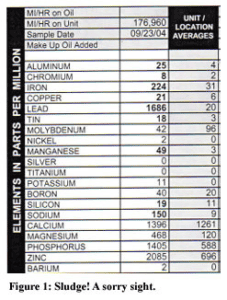

After pulling the first sample, I was glad I hadn’t seen it before I bought it. This engine had clearly been used and abused, which was to be expected for a former work truck with over 160,000 miles on it. (See Report #1 B30210.) I felt that if I changed oil several times over the next few thousand miles, I would be able to clean the engine up and hopefully get another 100,000 miles out of it.

This truck was not my daily driver, so the high idle problem and poor wear weren’t too big of a concern. After about two years, I pulled the original carburetor and had it rebuilt by a shop. This seemed to help for about 500 miles, and but then the high idle came back. I was also finding a lot of fuel dilution in the oil. I attributed the idle and fuel to a poor rebuild of the carburetor and my fix was to curse the guy who did the work. This didn’t help the problem, though the truck always started when I needed it, so I didn’t feel the need to try and fix it again.

Smoke on start-up

Eventually the day came when I started seeing some smoke on start-up. At first it wasn’t too bad, just a little for about a minute, but then it stared getting worse — bad enough that the smoke killed all of the mosquitoes in a two-block radius. I was told that replacing the valve seals should fix this, so I decided to take the truck out to my Dad’s barn in Ossian and tear into it.

Ossian is a little town abut 15 miles south of Fort Wayne, and among its many charms is its zip code: 46777. Maybe their town slogan should be “Get Lucky in Ossian!” Or maybe not. Anyway, Dad’s barn wasn’t the best place for engine work, mostly because it didn’t have any doors, had a dirt floor, poor lighting, and birds lived everywhere, but it was better than working on the street.

I dug into the engine hoping that I would just be able to remove the heads, get them cleaned up, replace the carburetor and we’d be back on the road. Unfortunately, when I removed the valve covers, that’s when I ran into my first problem: sludge! Not just a little hidden in the nooks and crannies of the head, but large chunks the size of a golf ball. (See figure 1 and C27858.) This was my first sign that the engine might need a little more love than I have figured on.

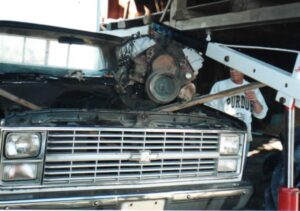

After removing the oil pan and finding some scored bearings, I decided to pull the whole engine and do a complete rebuild. So I borrowed an engine puller, got the engine loose, and hooked up the chains, and ran that’s when I ran into my second problem. The puller I borrowed was made for a car and I could not clear the radiator, even after jacking up the puller as far as it would go.

Removing the engine

To get the engine out, we had to lower it onto some wood blocks and hook one removable chain link from the puller arm to the webbing between the holds of the carburetor intake. This was a dicey maneuver to say the least, but it worked. I was originally thinking about swapping out the steel intake manifold for an aluminum one, but after seeing the strength of the original steel one, I was too impressed to scrap it.

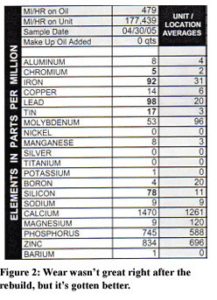

Once we got the engine out, I commenced to pull it apart. I got the major parts cleaned, replaced the bearings, painted it up nice, and put it all back together. It took about a month and it was late October, but I finally had it all back together and looking pretty.

I used the same method to get the engine back into the truck. All the necessary parts went back on and I eventually got to the point at which I was ready to start it up. At the much-anticipated turning of the key, I ran into the third problem: nothing happened. Sure, the starter was trying to turn the engine over, but the engine itself was locked up solid. After some discussion, we decided I may have mixed up the order of the rod-end caps, and this acted like a clamp around the crankshaft and prevented it from turning. In hindsight, I guess I should have realized something was wrong when the engine was out and it took a crowbar on the flywheel to make it turn so I could adjust the valves, but hey, that’s hindsight, and I was a rookie.

Well, it being late October in Northern Indiana in an open barn with no heat, I didn’t really look forward to the prospect of pulling the engine out again, doing another rebuild, and then putting it all back together. Fortunately, we had just bought a new building for Blackstone to move into. It was a construction building in its previous life that had a nice big garage, a chain hoist, and a heated workshop. So we loaded the Custom Deluxe onto a flatbed and had it taken to the new building.

After a few months of off-and-on work, I had the engine back in place and ready to start up. This time it cranked over just fine and eventually started with some timing adjustments and only a little eyebrow hair burned off during a backfire.

The first few oil reports weren’t pretty, but it’s been 8,000 miles and five years since the rebuild and I’m happy to say it’s still running well. It’s still not wearing as well as I would like, but the truck doesn’t see a lot of use, so I blame that on corrosion due to inactivity. The fuel dilution is pretty much gone and I don’t get any smoke on start-up, so all in all it was a successful job.

Now that the engine is pretty much past wear-in, I’ve decided to start experimenting with it. There has been a lot of talk lately about the importance of zinc in an engine. All gasoline engines oils have an additive called zinc dithiophosphate. It’s an anti-wear additive and is normally present at a level between 500 ppm and 1,000 ppm. Apparently, newer gasoline engine oils are dropping their zinc level and this is causing cam failures in flat-tappet engines. Being a bit of a skeptic, I’m not sure this is the case, so I’ve decided to use my freshly overhauled flat-tappet GM 350 as a test bed. Stay tuned for the next newsletter as I try running Aeroshell W65 in it — an oil that doesn’t have any zinc additive it in at all.

I’d like to thank Jim Stark (my Dad) for letting me use his barn and all the help he gave me during the process. Also C&P Machine shop for letting me know which rod end cap went to which rod (very important). And also my wife, for not throwing me out during this project.