In the Thick of it!

Analyst Chris Tulley hits the Hot Rod circuit and reports the effects on his oil

In the spring of 1995, the editorial staff of the tenured HOT ROD magazine had a decision to make. The publication was set to host a run of brand-new HOT ROD Power festivals, muscle car meet-ups where locals could show off their own rides, see cutting-edge tech from manufacturers country-wide, and dream of new, faster ways to drain their bank accounts. Said magazine staff wanted to be a part of the fun and show off their own project cars, which would prove difficult, as they were based in Bakersville, Ca., while the inaugural Power festival was set in Norwalk, Ohio. The solution; drive their heavy Chevys, rat rods, and budget dusters over 2,000 miles to Ohio, then say a quick prayer to Lee Petty and the motor spirits that they could make it back home. 200 other drivers joined the ranks, sparking the birth of the HOT ROD Power Tour. “My car doesn’t just have to sit at a car show, I can drive it.”

So here’s the gist. Five racetracks in five days, spanning stretches of American highway and automotive history. The 30th annual HOT ROD Power Tour just wrapped up June 15th, where over the course of five days, over 5,000 cars, including my own 1970 Chevelle, and at least 100,000 attendees came together to sweat out 1,800 miles of tour.

Bouncing from drag strip to road course, this year’s tour kicked off at the National Corvette Museum in Bowling Green, Ky., where the tour ended in 2023. Bright and early Tuesday morning, the caravan headed south to Nashville Superspeedway, where participants could spin a few laps. Day three; The University of Louisville. Next stop, National Trail Raceway, outside of Columbus, Ohio. The checkered flag flew over mecca; the Lucas Oil Raceway in Indianapolis. That’s where the tour will start in 2025.

I wanted to know how a tour like this would affect our favorite topic; my oil. I have been blessed to go on about 10 Power Tours so far with my father and our Chevelle. This is the third engine in the car, and I’ll have a fourth upgrade next year. This year we ran a 1969 Chevy 355cid small block. So I wanted to know how the oil looked to start, and what condition would it end up in nearly 2,000 miles later.

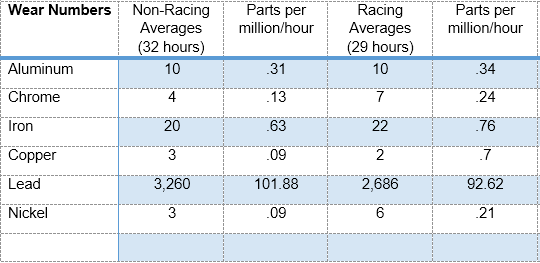

First, we took a sample of virgin Valvoline Full Synth 10W/30 (Figure 1). Calcium, a detergent-dispersal additive, was the leading element at 703 ppm. Magnesium, zinc, and phosphorus all read above 500 ppm, and there was some boron and molybdenum in the mix as well. Pretty typical cocktail of additives, overall. The TBN started at 5.3. The higher that TBN reads, the better active additives can stave acidity and corrosion.

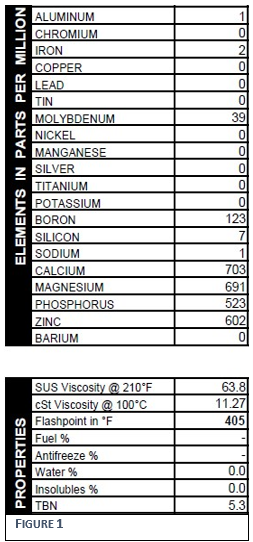

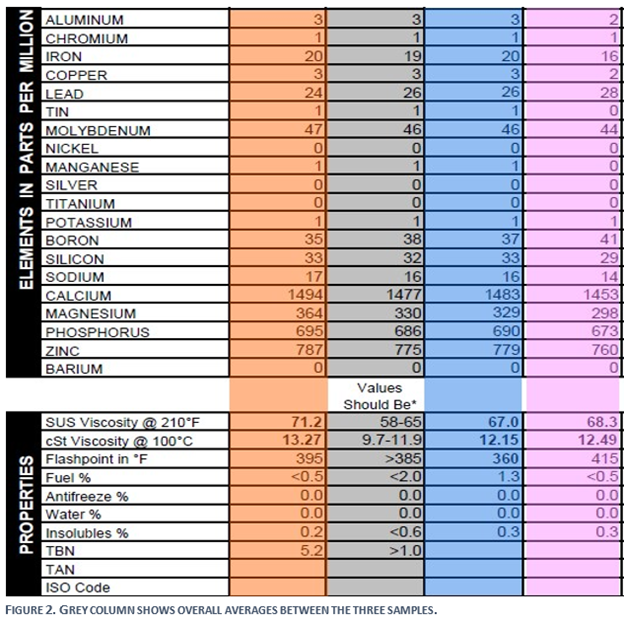

For the second sample (Figure 2, pink column), we drained the engine, added the Valvoline, and immediately pulled a sample via the dipstick. There was some iron and lead present from the previous fill, at 16 and 28 ppm, respectively. Carryover is inevitable, as oil changes fail to get every last drop out of the galleys channel of the block. We had used an oil additive recently, something along the lines of Lucas Oil, so calcium bumped up to 1,453 ppm. Zinc and phosphorus jumped up a little as well, but magnesium dropped by over 50% to 298 ppm. The viscosity increased as well, as did the amount of insolubles, so maybe that magnesium was grabbing carbon build-up to keep it from settling and coagulating. At least, that’s my idea of what a detergent dispersal does. Why the magnesium decreased is beyond my chemical knowledge. I’m more of an expert at “press gas, go fast”, it seems.

Sample number three (Figure 2, blue column) looked better than I expected, which is good for the engine, but it doesn’t make for the most exciting article. We pulled the sample in the middle of the week, then topped of the engine with about 4 ounces of fresh Valvoline. This sample saw roughly 900 miles of highway and backroads, and only an hour of road course time. As much as I wanted to drag race throughout the week, my tire budget didn’t approve.

The most notable addition to this analysis was fuel dilution at 1.3% by volume. Did the engine get above 190°F during this run? Obviously. But think of how many times the engine was stopped and restarted. Between gas stations, hotels, breakfast, and the many times I decided I needed a better parking spot, I bet we cranked the engine at least 15 times a day. That’s ample opportunity for fuel to enter the block. It wasn’t enough fuel to thin the viscosity below specifications for 10W/30, which is the main concern with fuel in oil. Fuel wasn’t present in any of the other samples. Iron, from steel parts like cylinders, shafts, and lifters, is the wear metal that tracks closely with use, and it increased by just 4 ppm. Lead dropped by 2, showing that the bearings didn’t wear a bit. That’s encouraging, because I certainly got on the throttle.

The final sample (Figure 2, orange column) reveals a cool instance of cause and effect. So imagine thousands of hot rods coming through a small town in southern Kentucky. Every red light, every stop sign was backed up for miles. There wasn’t a single Slim Jim or Diet Coke left in the county. I have radiator for a big block, and two electric fans to combat engine overheating. At one point, in the bumper to bumper traffic, my fan relays blew, and my engine temps rose to nearly 260°F, roughly 40° too high for comfort. As we were literally sweating out the situation, my oil was unable to cool the engine, an imperative feature that could have resulted in a tow-ride home.

After replacing the fuses, we never had another mechanical issue. The viscosity of the sample came back thicker than expected for 10W/30, an obvious sign of the high heat. Now if you think a little heat can impair classic American ingenuity, you’d be right in a lot of cases. But not mine. Iron read at 20 ppm once again. Sure, take into account up to 5% deviation from the testing equipment. Maybe iron was actually at 18 or 22 ppm. Either way, running at high temps without a fan did cause my oil to thicken a bit, but it didn’t hurt the wearing parts at all. Not a single increase in wear metals down the line.

The last kicker was the TBN reading. We only tested it on the virgin and the final samples, to see an exact start and finish. Remember when I said the TBN read at 5.3 in the virgin sample? It ended at 5.2. 1,896 miles later, and the active additive in the oil only degraded by a fraction of a decimal. The low end of a TBN is 2.0. After that, an oil can turn acidic, leading to corrosion.

Not only is that a testament to the additive package in Valvoline (not sponsored, but willing), but the overall efficacy of the engine and the American spirit.

We’ll see how next year goes, but no matter what, my Pops and I are in it for the long haul. Happy 30th Anniversary, HOT ROD Power Tour!