TBNs & TANs: Part 2

In our last newsletter, we did a deep dive on the science behind the Total Base Number (TBN) and Total Acid Number (TAN), and what information we can (and can’t) glean from these tests. Go back and check that one out if you missed it. For this article, we went into the lab for a more hands-on approach, and encountered a few surprises along the way. Let’s roll up our sleeves and start experimenting!

How Does Heat Affect the TBN?

We know a variety of factors impact the acidity of engine oils, but we wanted to isolate just one variable to measure its impact. Heat was the obvious choice, for two reasons. First, overheating is a common problem, and we often find increases in wear, viscosity, and insolubles after even brief overheats, so clearly heat causes the oil to change. Second, heat is pretty easy to replicate in a laboratory setting. So we broke out the hot plate and got to work!

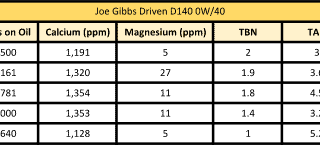

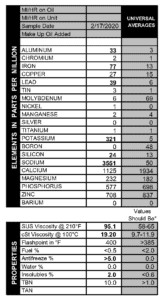

We took three samples of Rotella T 15W/40 and tested oil at three different temperatures:

-212°F (normal operating temp)

-302°F (upper end of most oil temp gauges)

-392°F (a temperature your oil hopefully never sees, at least not for long!)

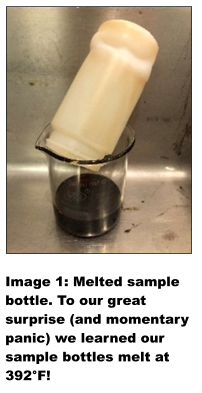

After reaching the target temperature, a portion of each sample was removed at 2-hour intervals throughout the 8-hour work day. It would have been nice to continue past 8 hours, since that’s really not very long in the oil analysis world, but fear of burning down the lab kept us in line. And once we took the first 392°F sample (see Image 1), our fears were vindicated.

The most obvious change we noticed was color. Image 2 shows that heat alone caused the oil to darken over time, and you can even see a color change between 302°F and 392°F, in Figure 3 below. So something is definitely happening as the oil gets hotter, but does it affect the TBN?

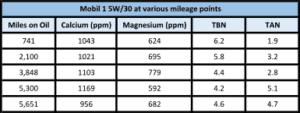

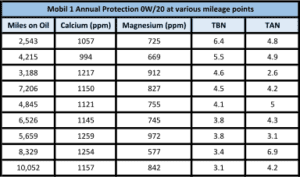

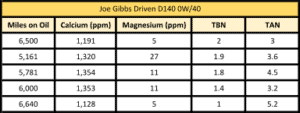

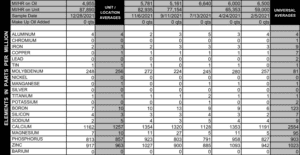

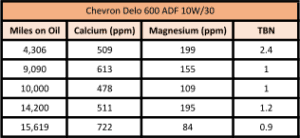

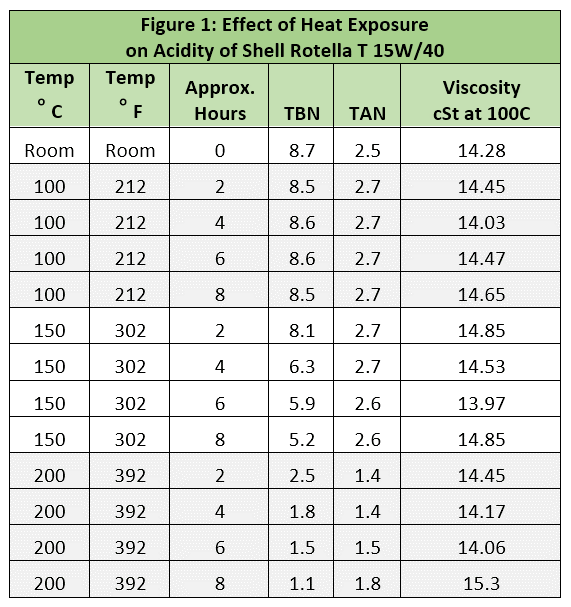

Once all the samples were collected, we tested the TBN, TAN, and viscosity, with the results shown in Figure 1. Eight hours at normal operating temperature had virtually no impact, and even at a relatively high 302°F, the TBN only dropped slightly over time. At 392°F, however, the TBN took a nosedive. By the 4-hour mark, it was already down to 1.8 — low enough that we wouldn’t suggest running the oil any longer — and it kept going down from there.

Even though this is a small sample size, the data clearly shows that high temperatures do cause the TBN to drop more rapidly, and the effect is more pronounced as time passes. Heat is far from the only factor impacting active additives out in the real world, where the oil also has to deal with the negative effects of friction, contamination, and fuel blow-by, just to name a few. But it doesn’t seem farfetched to think some of the damage from overheating could be linked to a diminished capacity to neutralize acids, so the TBN might be worth tracking in those instances when oil temps end up off the charts.

Surprising Finds

It’s worth noting that the TBN fell without throwing the viscosity out of whack — even the 8-hour sample at 392°F, the only one that ended up obviously thicker, was still within the normal range for 15W/40 (12.7 to 15.8 cSt at 212°F). We typically associate a thicker viscosity with “heat damaged” oil, but except in extreme circumstances, it looks like that viscosity increase is likely due to other factors, like high friction causing a breakdown of viscosity-improving additives, rather than just the heat itself.

Another surprise was that the 392°F samples also had a noticeably lower TAN reading. If you remember from the previous newsletter, the TBN tends to go down the longer the oil is used, and the TAN tends to increase, so at first this seems like a really weird result. What’s going on here?

Well, it’s important to remember that the TBN and TAN tests technically measure two different things. The TAN is a measure of how acidic the oil is, while the TBN measures the oil’s capacity for neutralizing acids. It appears that the excess heat has caused a chemical reaction that caused the oil to become less acidic while at the same time reducing the oil’s capacity to neutralize acids, likely by damaging the TBN-boosting additives or causing them to fall out of suspension. If this were a real used oil sample, acids would also be building up due to the other factors in the engine we mentioned above (contamination, blow-by, etc.), causing the TAN to increase. But since this was a controlled experiment where heat was the only variable, that didn’t happen here.

A Colorful Surprise

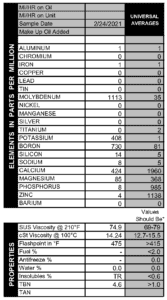

Before we end: a mystery! While we researching this article, we got curious about Aeroshell 100 Mineral oil. In theory, this type of oil shouldn’t have any additives at all (the normal additives in automotive oil can cause catastrophic detonation in aircraft engines), so we wanted to confirm that this oil would start out with a 0.0 TAN (it did) and a low TBN (also true at 0.0).

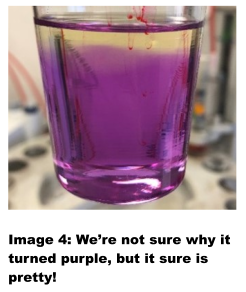

What we weren’t expecting was for the titration solution to turn bright purple! Usually samples stay evenly light yellow throughout testing, but once the basic solution (potassium hydroxide and isopropyl alcohol – the “Bruce” from Part 1) was added to this sample, the color drastically changed. A few minutes later, it began changing back to yellow and you can see that process beginning in Image 4. This made us even more curious, so we found a bottle of Aeroshell W100 (which does have some ashless-dispersant additives) and measured its TAN and TBN as well. They were 0.0 and 0.2, respectively. And lo and behold, this sample took on the same cheery magenta once the basic solution was added.

We aren’t sure why this happened, but we have a guess. Phenolphthalein is a pH indicator used in some other sorts of acid-base titration. It turns purple in basic solution, in the same way litmus paper turns blue. Phenolphthalein won’t show up in our spectral exam, since it’s made of the same elements as oil (C20H14O4), but maybe it or another pH-sensitive substance is present in these oils? We’re not sure! If you know the answer, we’d love to hear from you at bstone@blackstone-labs.com.

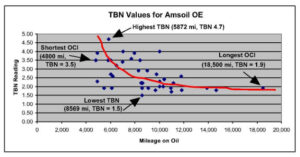

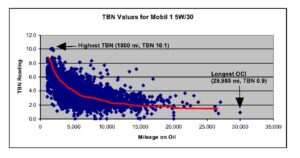

Answering the question! So, back to the main question — Do you need a TBN or TAN? The results of our experiments suggest that these tests can be helpful, especially if your engine oil got much hotter than it should. If you’re not having a problem with temps though, the main reason to get a TBN is what we discussed in Part 1 — seeing if the oil can be run longer.

In either case, the TBN or TAN readings provide additional data points, but they don’t replace the information on wear levels and physical properties found in the standard oil tests. Whether you’re concerned about heat damage or just looking to run a few thousand miles longer on the next oil, we look at all of the data to answer your questions and give you a complete picture of the engine’s health.